🌐 Introduction

The US Tariff–India trade war is not only about tariffs, trade deficits or oil in 2025. It’s a battle for technology corridors, for financial plumbing, for supply‑chain sovereignty, for the new, rising map of geopolitical alignments from the Indo‑Pacific to West Asia. The tariff volleys — all coming alongside debates on data localization, sanctions compliance, and export controls — have raised a larger question: can India defend strategic autonomy while embedding itself further into a world that is dividing into competing economic blocs? This is an inflection point for India’s businesses. For households, it is a reset of prices, jobs, savings strategies. For policy makers, the balancing act is the most difficult since 1991: create growth engines without surrendering leverage; court capital without welcoming vulnerability. Here’s a long‑form explainer about how we got here, why “beyond oil” is important, which sectors are in the blast radius, and how India can make friction resilience.

Meta description: The 2025 U.S.–India trade war is a geopolitics struggle over tech, finance, and supply chains—not just oil. See impacts, scenarios, and playbooks.

🧭 How the skirmish stretched beyond oil

Crude imports, LNG contracts, refinery upgrades For years, energy had been top of the bilateral narrative: crude imports, LNG contracts and refinery upgrades. In 2025, the agenda widened. The U.S. intensified tariff coverage to consumer goods and intermediates; semiconductor cooperation debates and export controls further intensified; digital policy took center stage as both the US and the EU challenged the boundaries of data protection, AI governance and privacy. Economically, questions of sanctions enforcement, payment rails, and correspondent banking risk morphed an old‑fashioned tariff narrative into a multi‑front test for geopolitics. India’s three-pronged response to ‘diversify, deepen manufacturing and build trusted supply chains with stakeholders in EU, GCC, Japan and ASEAN’ is a structural pivot whose tail will far outlast any single round of tariff saddle.

🧩 Why this is a geopolitical battle, not a pricing tiff

- 🛰️ Technology sovereignty: Who controls chips, cloud, AI compute, and critical minerals shapes military and economic leverage.

- 🧮 Financial plumbing: Access to dollar liquidity, clearing networks, and de‑risked correspondent banking decides trade velocity.

- 🚢 Sea lanes & chokepoints: The Indo‑Pacific, Hormuz, and Malacca determine shipping insurance, container routing, and inventory buffers.

- 📜 Regulatory reach: Export controls, sanctions, and data‑flow guardrails increasingly decide unit economics.

- 🧭 Alliance geometry: Quad, I2U2, and ties with EU/GCC/Japan create overlapping corridors that either cushion or amplify shocks.

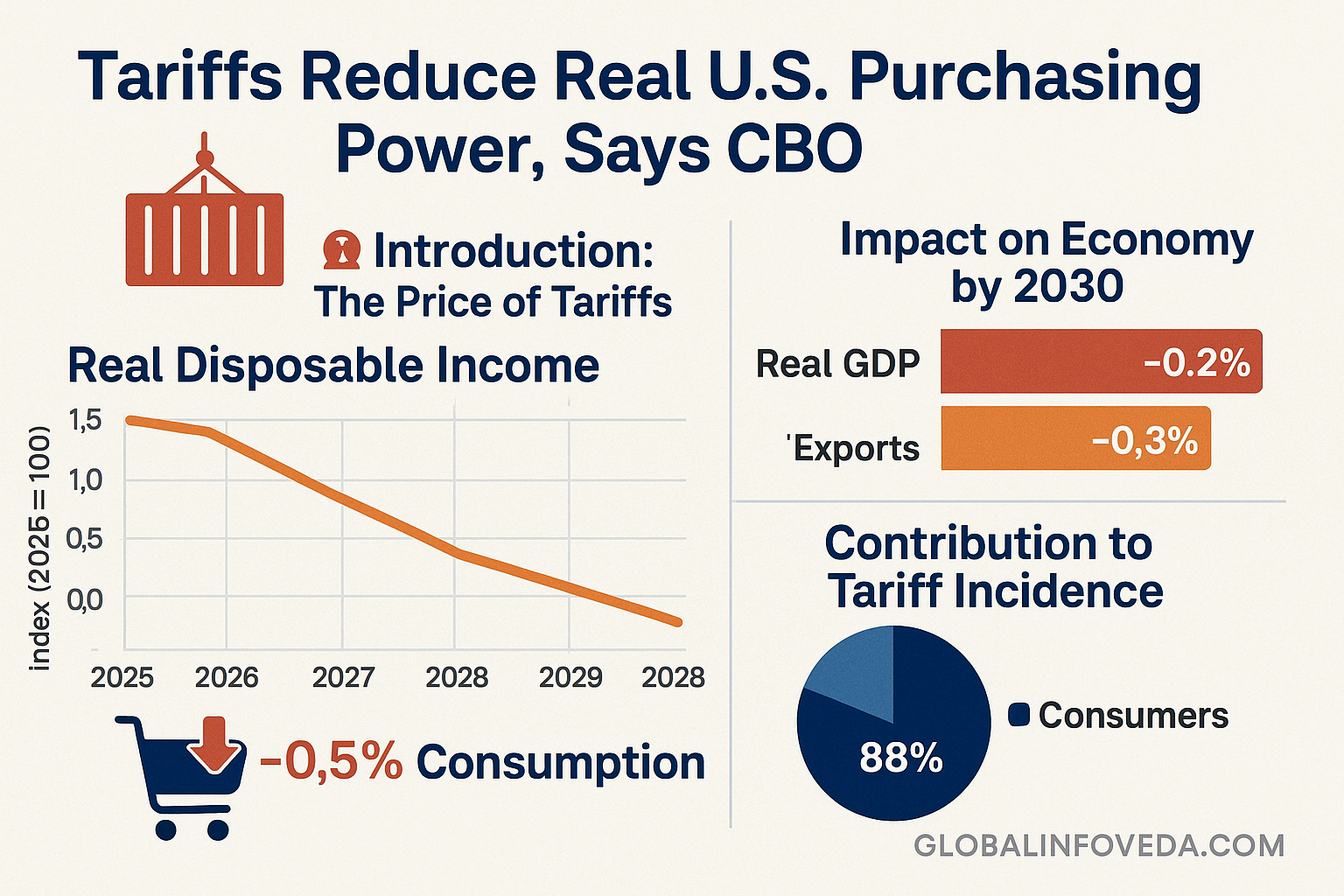

📉 How tariff arithmetic morphs into macro risk

A tariff is a cost line, in normal times. Highlighted here under 2025 volatility, that duty wedge is inflamed by freight, insurance and retail pegs and also credit. A 25‑point duty increase can push shelf prices up much higher than mere minimals effectively once markdown budgets and promotion weeks are factored in, but buyers refuse to breach $9.99/₹999 psychological pegs, so they shrink pack sizes, downgrade specs or cancel altogether. For export hubs like those found in India, spanning from Tiruppur to Surat, Panipat to Kakinada, this means stop‑start lines, stretched receivables and working‑capital crunch. Banks then toughen their terms; capital spending is postponed; secondary jobs in decoration, packing, logistics dry up. Macro risk isn’t just about GDP math; it is a local problem.

🧮 ⚖️ Comparison — three layers of the contest

| 🧠 Dimension | 🎯 What’s at stake | 🔧 India’s lever |

|---|---|---|

| Tech‑industrial | Semiconductors, telecom, AI compute, EV value chains | PLI, R&D credits, design‑in with allies |

| Financial | Dollar access, sanctions navigation, payment rails | IFSC hubs, trade credit insurance, FX risk hedging |

| Normative | Data flows, privacy, AI ethics, standards | Digital India Act, interoperable compliance, trusted corridors |

🇮🇳 India lens: which sectors sit in the splash zone

Because of retail peg rigidity, textiles & apparel can be hit; gems & jewellery finds itself hit by both tariffs and a shift to lab‑grown; seafood falls back on menu pricing and cold‑chain reliability; auto components swing with platform; specialty chemicals have seen embargo/ substitution as buyers are testing Mexico/ EU/ ASEAN alternatives. Electronics assembly, handsets and IT hardware exist in the crosshairs of export controls and value‑chain adjustment, transparency of origin tracing, and “trusted vendor lists” are essential. Meanwhile, services — IT-BPM to fintech — are contending with second‑order demand wobbles as U.S. clients rethink discretionary spends.

🧠 The geopolitics inside supply chains

- 🔗 Friend‑shoring vs near‑shoring: India wins when it offers process control, compliance, and capacity—not just lower wages.

- 🧭 Rules of origin: Buyers demand traceability; exporting via hubs without documentation is a dead end.

- 🔋 Critical minerals: Batteries, semiconductors, and grid storage hinge on lithium, nickel, cobalt, and rare earths; India needs upstream bets and recycling.

- 🧫 Standards as strategy: Meeting REACH, RoHS, and AEO norms is now a growth lever, not a cost nuisance.

- 🌐 Digital corridors: Cross‑border data regimes and AI governance dictate which cloud regions and vendors you can use.

🔮 Scenarios for the next 12–18 months

Relaxation: Partial deferment of HS line carve-outs; quota windows re-open onhold SKUs; rupee steadies; exporters re-launch SRPs. Sideways: Tariffs stick; order cycles collapse; rolling POs and promotion‑week alignment rule. Escalation: Duties expand; export controls tighten; cash firewall and contract triggers more material than top‑line. On all three, companies that can alternate between value and premium specs without crushing their brand value will survive the tempest.

🧰 Playbook for Indian exporters right now

- 🧭 Dual finishing: Keep core processes in India; move final finishing/pack to duty‑neutral hubs to retain partial U.S. volumes.

- 🧪 Spec agility: Maintain value/premium pairs per SKU so retailers can defend pegs without eroding brand.

- 🌍 Market mix: Warm up EU/Japan/GCC/ASEAN with pre‑booked audits, translated catalogs, and traceability dashboards.

- 📦 Carton science: Cut volumetric weight and improve container fill; pair with shared freight consortiums.

- 💱 FX discipline: Book micro‑layers of forwards weekly; avoid hero trades.

- 🧾 Contract refresh: Add policy‑shock clauses, currency bands, and Incoterms flexibility; pilot vendor‑managed inventory for anchor buyers.

🧮 🛒 Comparison — retail pegs vs reality and the Indian response

| 🏷️ Retail peg | 🧪 Buyer reaction | 🧰 Indian lever |

|---|---|---|

| $9.99 tees | Refuse MSRP change; demand spec downgrades | GSM tweak, three‑pack bundles, reinforced seams |

| $24.99 cookware | Delay re‑orders; test Vietnam/Mexico | Design pods, story‑led origin, small curated drops |

| $14.99 shrimp | Re‑engineer menu; push weekday portions | Value‑added marinated/breaded SKUs, EU/GCC channel shift |

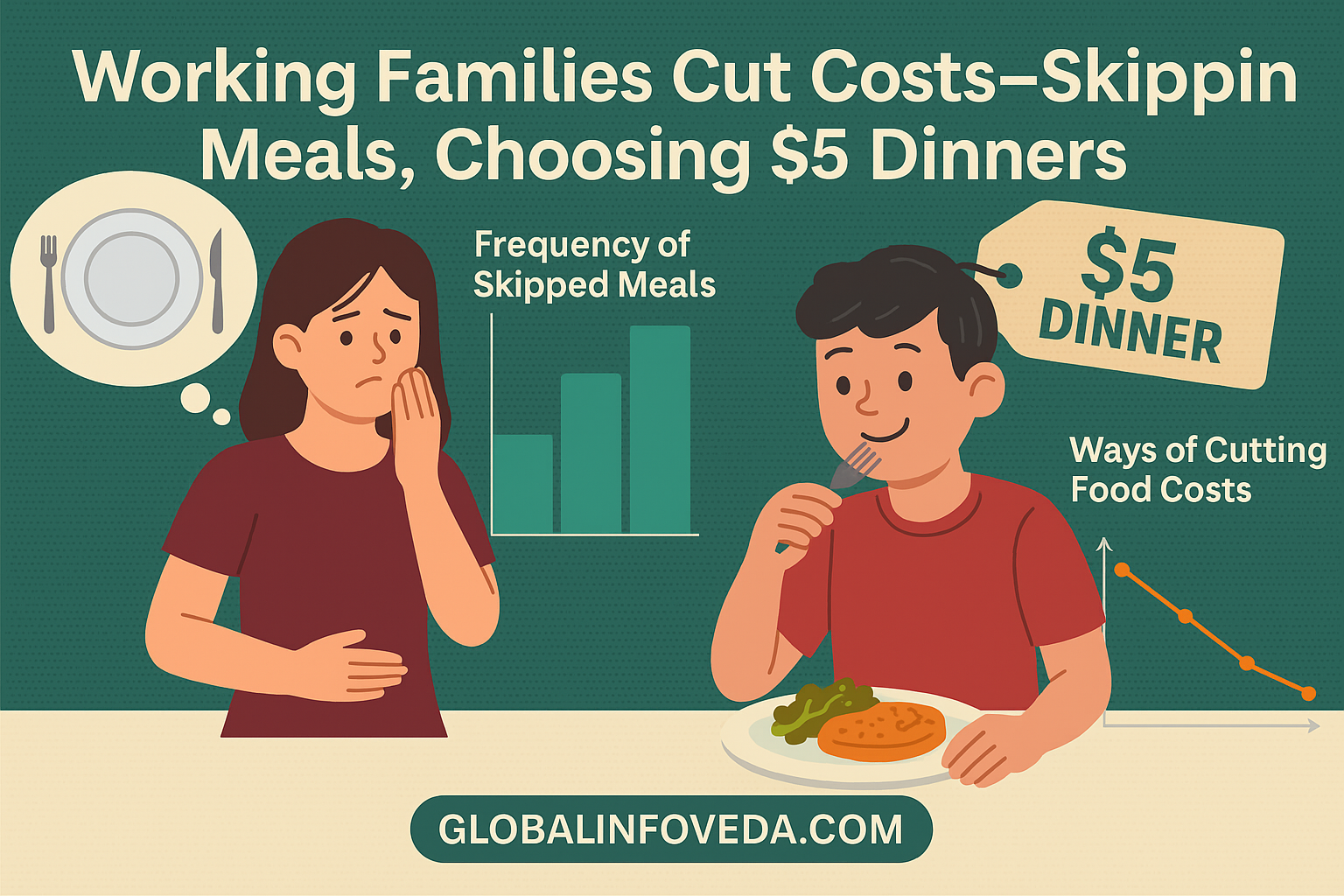

🧪 Case story — Tiruppur’s pivot to EU green specs

A knitwear MSME with 800 workers watched its U.S. orders fall 28%. The leadership created eco‑label micro‑drops with lighter GSM and better seams, pitched a German discounter, and partnered with two peers for shared freight. OEKO‑TEX and traceability dashboards won shelf trials; utilization recovered to 85% in two quarters.

🧪 Case story — Surat’s lab‑grown gambit

A mid‑sized diamond unit hedged its natural line with a lab‑grown capsule, shifted final polish to a duty‑neutral hub, and rebuilt U.S. independents via virtual try‑on. Employment held steady; women polishers moved into QC, where defect catches improved.

🧪 Case story — Kakinada seafood’s menu design

A processor co‑designed weekday portions and value‑added packs for U.S. chains while redirecting marinated/breaded formats to EU/GCC. Cold‑chain partnerships improved container utilization; farm exits slowed.

📈 India’s financial resilience—what the plumbing must deliver

India wants predictable dollar access, easier trade credit and liquidity tools that are market‑neutral. The RBI can draw on FX windows to avoid disorderly moves, while fine-tuning durable liquidity to keep banks lending to export clusters. Hubs in the IFSC style can play host to supply‑chain finance, invoice discounting and credit insurance marketplaces, which shave the cost of risk. At the same time, see-thru cluster dashboards — orders, hours worked, returns — help states deploy support (like creches, safe transport, skilling) into QC and machine ops so labor doesn’t pull out of factories.

🧠 The tech‑norms front—where policy creates leverage

- 📜 Data flows: Align with partners on privacy, security, and localization that still allow cross‑border compute.

- 🧠 AI governance: Interoperable models for safety, traceability, and dataset provenance make Indian AI exports credible.

- 🛰️ Semiconductor MOUs: Focus beyond fabs: OSAT, IP blocks, EDA talent, and design‑for‑manufacture with allies.

- 🔋 Battery & grid: Anchor recycling and materials consortia; hedge upstream dependence on a few mineral suppliers.

💸 Household lens—what Indian families can actually do

- 🧾 Budget resets: Re‑cast monthly spends for food, fuel, and EMIs; allow for imported‑input shocks.

- 💳 Debt hygiene: Prepay high‑APR balances; avoid floating‑rate borrowing unless income is stable.

- 🪙 Gold as volatility buffer: stagger entries; don’t lever.

- 🛒 Smart consumption: Prefer durables with repairability; avoid panic buying; watch combo offers not just ticket price.

- 💼 Savings ladder: Keep 3–6 months expenses liquid; ladder FDs to smooth rate risk.

🧰 MSME finance: keep factories warm

- 💱 FX micro‑layers and clear hedge policy signed by the board.

- 🧾 Receivable discounting across platforms; don’t rely on one lender’s risk appetite.

- 🛡️ Selective credit insurance for the top buyers; use premium savings to fund QC and testing.

- 📉 Options around policy dates; covered calls on surplus inventory hedges.

🧠 State‑by‑state nuance in India

Tamil Nadu/Punjab face apparel shocks faster; Gujarat balances gems with chemicals and engineering; Andhra and the east coast feel seafood ripples; Uttar Pradesh leans on design upgrades in metalware/leather. Policymakers who deploy testing labs, buyer roadshows, and cluster services (transport, creches, hostels) will shorten the downcycle and improve retention of women and migrant workers.

🧮 📊 Comparison — three destination corridors India can scale

| 🌍 Corridor | ✅ What fits now | ⚠️ Watch‑outs |

|---|---|---|

| EU | Home textiles, functional apparel, chemicals | REACH costs, energy volatility |

| GCC | Jewellery, seafood, homeware, fast fashion | Price sensitivity; USD‑linked FX |

| Japan/ASEAN | Auto parts, functional fabrics, electronics adjacencies | Certification time; high quality bar |

🔎 Investor lens—how to avoid getting steamrolled

- 🧭 Exposure map: Rank holdings by U.S. revenue share and pricing power; avoid names that only win on price.

- 🧮 Balance sheets: Prefer low net debt, liquid inventories, diversified buyers; watch DSO.

- 🧱 Hedges: Use forwards and protective puts; finance via covered calls on rallies.

- 🌱 Rotate thoughtfully: Domestic beneficiaries of import substitution; exporters with EU/Japan runway.

- 🧪 Earnings revision watch: Add quality after capitulation, not before.

🧪 Case story — Moradabad’s design defense

A brassware exporter lost big‑box orders; it built a design pod and sold story‑led collections to independents in the U.S. Northeast and EU. Limited‑run serveware at higher ASPs offset volume loss; a store‑in‑store trial with a European chain followed. The win came from content, origin story, and operational reliability.

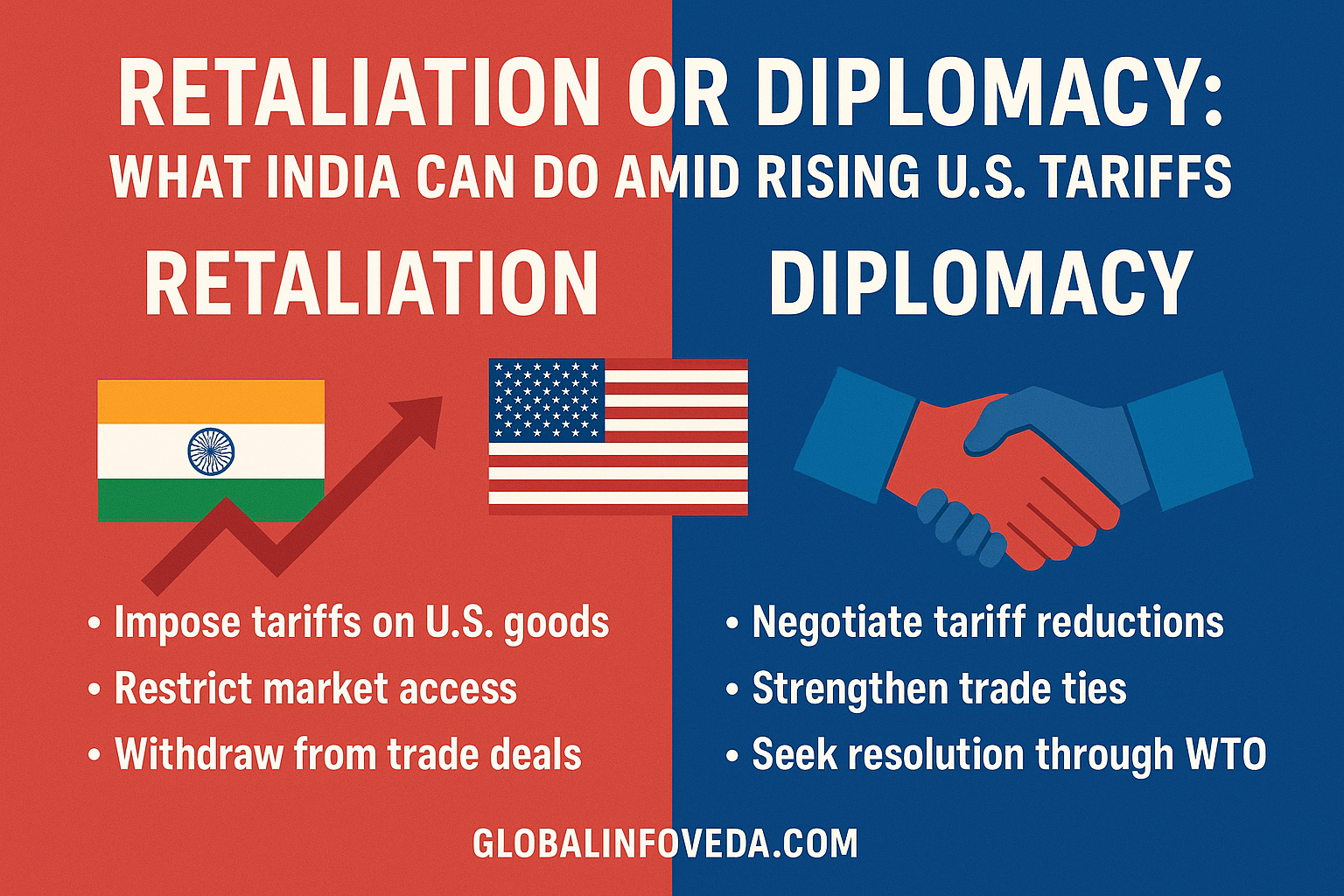

🧭 Diplomacy that moves the needle

- 🧳 HS‑line diplomacy with data‑rich submissions for carve‑outs where U.S. consumers face visible price spikes.

- 🧰 Mutual recognition of AEO and paperless customs corridors to reduce dwell time.

- 🤝 Buyer missions in EU/Japan/GCC with curated cluster catalogs; leverage IFSC structures for trade finance on‑site.

- 🧪 Quality grants (effluent, REACH, testing) tied to milestones instead of blanket subsidies.

🧠 Media and narrative—why messaging matters

India is not a low‑cost pitch; it is a reliability‑and‑quality pitch with cluster depth. The message to global buyers should foreground compliance, sustainability, and craft. Domestically, communication must be precise: what the state watches (orders, DSO, hours), what help exists (creches, hostels, labs), when it ends (sunset clauses)—so that relief stabilizes rather than distorts.

🧰 Corporate housekeeping—small levers, big outcomes

- 🏷️ Carton redesign to cut volumetric weight.

- ⏱️ SMED on sewing/finishing to lift throughput.

- 🔎 First‑pass yield tracking post spec‑cuts to prevent returns.

- 📦 VMI pilots with anchors to smooth demand.

- 🛰️ GPS‑tagged pallets and ETA feeds to reduce buffers.

🧠 City ecosystems—ports, finance, and talent

Mumbai and Gujarat ports need extended gate hours; Bengaluru/Hyderabad provide design/data/automation talent pods for exporters; Delhi‑NCR hosts buyer meets and policy dialogue. Cities that convert stress into sprints on compliance, design, and digital tooling will win the next cycle.

❓ Questions Indian firms keep asking

- 🙋 Does a weaker rupee fix margins? It cushions invoices but raises imported inputs and debt‑service costs; use gains for automation and compliance.

- 🙋 Will U.S. buyers share duty pain? For must‑carry SKUs, some will via spec changes and bundles. In commodities, expect shared pain.

- 🙋 Can we simply switch to the EU? Not overnight; allow 2–4 quarters for compliance and spec alignment.

- 🙋 Are warehouse clubs a safe haven? Often, because memberships accept bundles and occasional peg moves—but OTIF discipline is ruthless.

🧠 Myth vs fact

- ❌ “This is just about oil.” → ✅ It is about tech, finance, norms, and alliances that shape pricing for a decade.

- ❌ “Discounts defend shelf space forever.” → ✅ Quality and on‑time reliability beat endless cuts.

- ❌ “Wait it out and it will pass.” → ✅ Build scenario drills and dual specs now; speed is the edge.

For the market‑wide shock narrative: “Liberation Day” Tariffs Spark Stock Market Crash of 2025

🧭 Leadership checklist—boards and CFOs

- 📊 13‑week cash flow live at board; firewall 90–120 days payroll/utilities.

- 🧬 Product rationalization: protect winners; drop long tail.

- 🧠 People plan: shifts, cross‑training, creches; retain women workers.

- 🧾 Contract sanity checks: policy‑shock triggers, currency bands, cost‑sharing.

- 🧪 Compliance cadence: testing, REACH, AEO, CoO digitization.

🕰️ Historical arc—how decades of choices set up 2025

Over two decades, relations between the United States and India had moved beyond sanctions and suspicion to encompass a bold agenda in defense, energy, technology and services. The 2005–08 civil nuclear rapprochement, successive defense logistics agreements and deepening IT‑BPM ties forged a lattice of trust, even as trade disputes over tariffs and market access remained a repetitive feature. The shale revolution remade the energy landscape by driving LNG into India’s mix and increasing private‑sector engagement with U.S. energy companies. India’s internal reforms in the form of GST, Insolvency and Bankruptcy code, PLI, and digital public rails like UPI, aimed to upgrade production base and slim friction. By 2025, that relationship was denser but more fragile: high-level interdependence in services and tech talent mashed into taller walls over tariffs, export controls and data governance. This current face-off is thus not a breakdown, but a stress test of an unusually complicated partnership — indeed, of the partnership — and of the friction between strategic autonomy and the physics of supply‑chain reality.

🛡️ Defense‑industrial angle—dual‑use tech and leverage

There is a silent but decisive battlefield at the intersection of dual-use technologies: sensors, optics, composites, and AI for ISR. Here, export restrictions bump up against India’s ambitions to have electronics, avionics and propulsion know‑how on which India is dependent “localised.” The U.S. calculus is to protect technology leadership while allowing enough access to keep India aligned on the Indo‑Pacific balance. India’s calculus: how to learn fast without getting path‑dependent on any single vendor. This tension plays out in conversations about semiconductor ecosystems beyond fabs — OSA Test, IP blocks, EDA talent — and in supply chains around unmanned systems, EW suites and precision machining. For India, success will resemble an increase in design‑in wins for domestically and foreign-certified components, which reduces the risk of sanctions or license shocks while pushing the quality ceiling for its homegrown integrators.

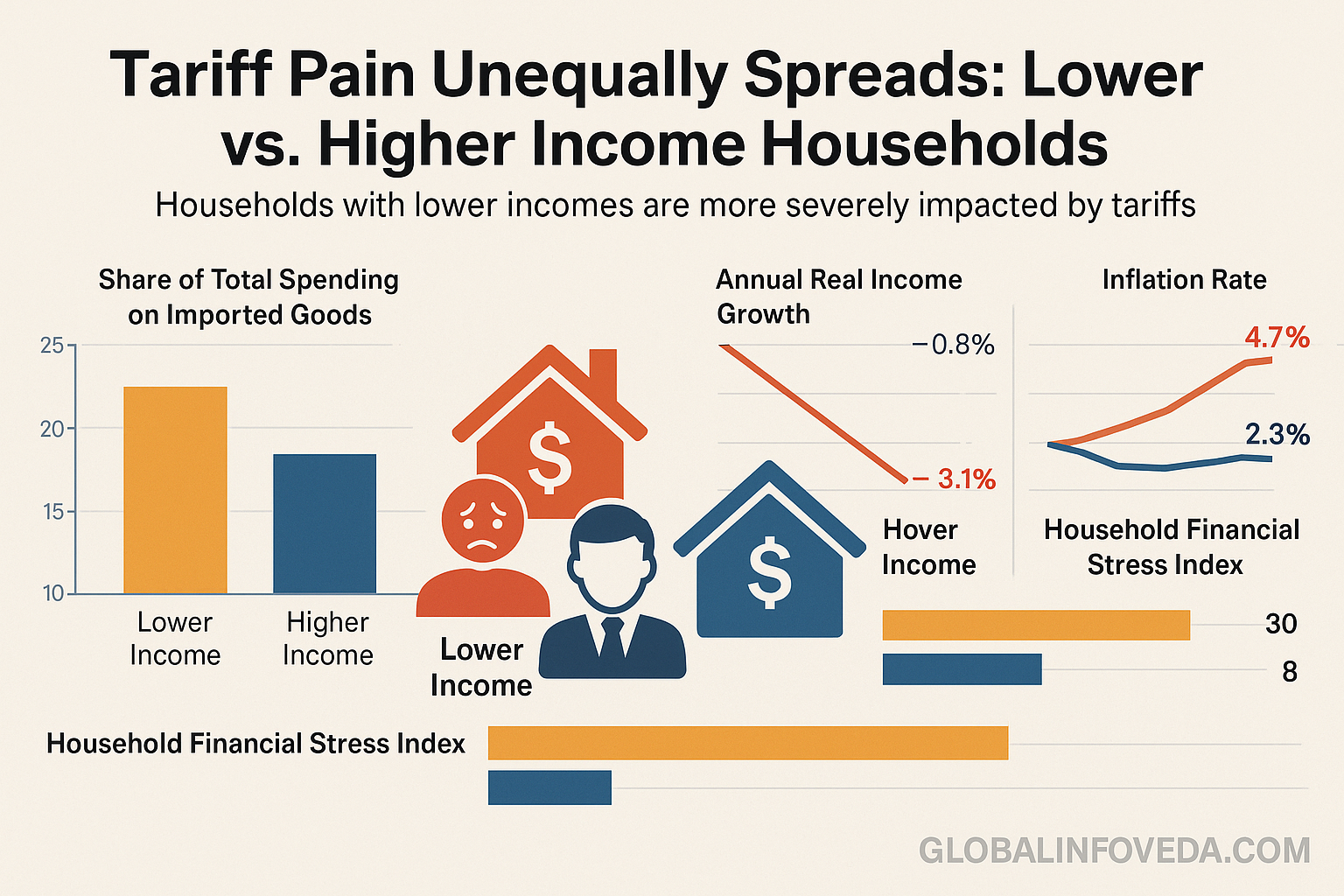

🧾 Domestic political economy—distributional stakes inside India

The shock of trade hits communities and regions unevenly. Knitwear towns with high women participation, like Tirupur, suffer sharper household cash‑flow volatility when shifts get cut; gems clusters damp demand swings through overtime cuts; while seafood belts depend on cold‑chain reliability as well as farm credit terms to keep pond fallows small. The auto‑component hubs must balance between OEM platform timelines and aftermarket buffers. The policy response that truly counts is granular: creches to stop women leaving shop floors, hostels for migrant workers, last‑mile skilling for QC and machine ops, and testing labs that help MSMEs win fussy EU/Japan approvals. In their absence, macro relief would have leaked; with them, India enhances its factor endowments and trades up the value chain even in a difficult external year.

🧠 Standards wars—why norms are the new tariffs

In a time of splintering, formal obligations are just one gatekeeper. As for standards — for safety, chemicals, cybersecurity, privacy and A.I. — they are more and more the price of admission to the market. For exporters the competitive advantage is not just lower cost production, but documentation, traceability and audit readiness. Indian clusters investing in REACH, RoHS, AEO, and digital CoO earn trust at the border and lower the risk of random inspection. In AI and cloud, compliant interoperability with partners – and the protection of data sovereignty — enables Indian firms to sell services to third parties without contravening cross-border rules. In short, the strategy is to approach norms like a product feature: the cost is the upfront price paid in access, the payoff is a form of access, and it’s something that gives you a say above and beyond rate cycles.

🧭 Alliance geometry—balancing many chairs at once

India’s alliance stance straddles Quad and minilaterals like I2U2 with closer links to GCC, substantial interface with EU institutions and pragmatic engagement with ASEAN and Africa. The trick is to maintain option value while not seeming to free‑ride. That is turning political capital into concrete corridors: mutual recognition of AEO, paperless customs, trusted data transfer systems, testing lab reciprocity. It also means showing up with bankable projects, not just communiqués, so that investors see predictable timelines and enforceable contracts rather than slogans.

🧰 Education and talent—building the pipelines that geopolitics needs

If the technology is choke, the talent is the choke. India’s chance is to expand STEM throughput while maintaining a broad river of applied skills. The returns would be disproportionately high for electronics, precision engineering and chemicals, when we invest to upgrade polytechnics, increase the number of apprenticeship sits, and incorporate system training into vocational training. For its white‑collar portion, scaling EDA-embedded systems ’nd semiconductor design tracks establishes a domestic base to accommodate OSAT-IP matrimony. In services, AI safety, model evaluability and data governance will be the skills that differentiate Indian companies as legitimate vendors in highly regulated markets.

🧪 Case story—Coimbatore pumps and process discipline

Coimbatore-based pumps cluster — supplying to agriculture, water and building services — was hit by volatility in steel and components, along with weak export orders. A group of MSMEs standardised on certain impeller designs, used the same third‑party testing lab, and consolidated purchasing of motors. By embracing carton science and route optimization, they cut freight spend and protected first‑pass yield. A European distributor took both specs (€7000 and €4500) based upon a three‑month reliability test, increasing margins without snapping retail pegs.

🧪 Case story—Noida electronics and origin proof

An EMS unit near Noida which served peripherals lost a U.S. line, as exports controls became stringent. Instead of chasing gray routes, it has rebuilt origin documentation, gained AEO and has a Japanese client who wants a traceable supply. The company brought a small design pod in-house to fiddle with firmware and enclosure tolerances, adding stickiness beyond assembly. In two quarters, utilization was back, and in 12 months, ASP’s improved, because “reliability,” it’s a brand.

🧭 Logistics reality—ports, rail, and compliance velocity

Trade tensions compound the costs of inaction. Each day a ship remains at port eats into working capital and increases the risk of chargebacks. India’s leverage isn’t just creating more berths but making the ones that exist predictable: extended gate hours during peak seasons, integrated risk engines that streamline inspections and consistent adjudicatory time lines. Rail‑port connectivity and multi‑modal hubs can save hours, and basic digitization—e‑invoicing, e‑CoO, slot booking—cuts gaming and queues. For clusters, consolidated shipments and milk‑run trucking reduce buffer stock, which means less cash is tied up.

💼 Investor behavior—narratives vs numbers

In a noisy year, the story lines swing faster than the numbers. Investors need to divide the first‑order from the second‑order. First‑order is the obligation wedge and immediate demand shock; second‑order is in progress upgrades, compliance wins, and buyer strike diversification that multiply in silence. Screens often underprice second‑order execution. Keep an eye on footnotes for inventory write‑downs, return provisions and contract liabilities. Follow headlines for EU/Japan customer adds, dual-spec approvals, traceability milestones. These inform you if a company is playing the long game. Opt for barbell exposure — domestic import substitution plus export names with pricing power — and let options express your volatility views for risk control.

🧠 Communication discipline—inside firms and with buyers

Operational excellence dies without communication. Inside factories, short daily stand‑ups that scan throughput, first‑pass yield, and rework rates keep teams focused. With buyers, sharing traceability dashboards and OTIF metrics signals reliability. With lenders, weekly DSO and order‑book updates build trust lines before a crunch. The goal is to collapse uncertainty: clarity converts marginal buyers and keeps finance flowing.

🧩 What success looks like by 2026

If India ‘does it’, the image 12 months on would include higher EU/Japan shelf share, greater dual‑spec approval of key SKUs, quicker customs clearance through the reciprocal AEO, and a noticeable bump in first‑pass yield across clusters. On the macro, services exports make the current account comfortable while goods adjust; rupee volatility narrows; capex restarts in targeted lines like chemicals intermediates / electronics sub‑assemblies / auto adjacencies. And, crucially, wage-losses are kept in check since women and migrant workers are brought back with creches, hostels, and safer commutes. The political dividend is silent but fundamental: the sense that India can weather storms without letting go of its growth script.

❓ FAQs—clear answers for leaders

- 🙋 Is decoupling inevitable? Partial de‑risking is, full decoupling isn’t. India’s job is to become the trusted node both blocs can use, not the orphan corridor no one prioritizes.

- 🙋 Should we chase every export “opportunity” that pops up? No. Filter by payment discipline, return history, and compliance burden. A small, reliable EU customer can beat a large, flaky one elsewhere.

- 🙋 Does capacity expansion make sense now? Selectively—if you have design‑in, dual specs, and a buyer willing to share risk via VMI or minimum off‑take. Otherwise, invest in throughput and quality first.

- 🙋 Will domestic demand fill the gap? Partly, in segments where import substitution is credible. But export capabilities shouldn’t be mothballed; they should be re‑skilled and re‑spec’d for alternate corridors.

- 🙋 How do we keep talent from leaving during a slow patch? Offer cross‑training, attendance bonuses, and predictable shifts; invest in creches and transport. Signal a path back to overtime when orders recover.

🧠 Personal analysis—why this moment is opportunity in disguise

Crises separate price‑takers from process‑makers. The ones who win won’t be the biggest and loudest in the social-media arena; they’ll be the ones tightening seams, cleaning data, and documenting process to the point where a skeptical buyer has no reason to say no. Geopolitics will keep throwing curveballs; norms will keep tightening. The hedge is competence, the kind that translates between markets because you can run it in the lab, see it on the dashboard and know when you’re manufacturing the Coda we all dream of, the product just works. India’s option is to bottle this competence into repeatable playbooks cluster by cluster until the tag “Made in India” is code for predictability.

📚 Sources

- Reserve Bank of India (RBI) — External sector bulletins and market developments: https://www.rbi.org.in/

- Directorate General of Foreign Trade (DGFT) — HS‑code policy and export facilitation: https://www.dgft.gov.in/

- World Trade Organization (WTO) — Trade policy monitoring and statistics: https://www.wto.org/

- U.S. Trade Representative (USTR) — Tariff announcements and country notes: https://ustr.gov/

🌟 Final Insights

The 2025 U.S.-India trade war is actually a battle over who gets to make the rules on technology, finance, and supply chains in a world that increasingly seems to be moving toward bloc competition. India’s optimal defense is offense: shift from commodity to capability, price‑first to process‑and‑design‑first, and ad‑hoc shipments to trusted corridors with verifiable proof of traceability. All that needs is for exporters to re‑engineer specs, for CFOs to harden cash walls, and for states to build cluster services, and for diplomats 45 to win HS‑line carve‑outs while wiring paperless ports and AEO bridges. Done as a package, this would enable India to maintain strategic autonomy while achieving greater relevance globally — turning a trade war into a decade‑long pursuit of higher‑quality growth.

👉 Explore more insights at GlobalInfoVeda.com