🔋 Introduction

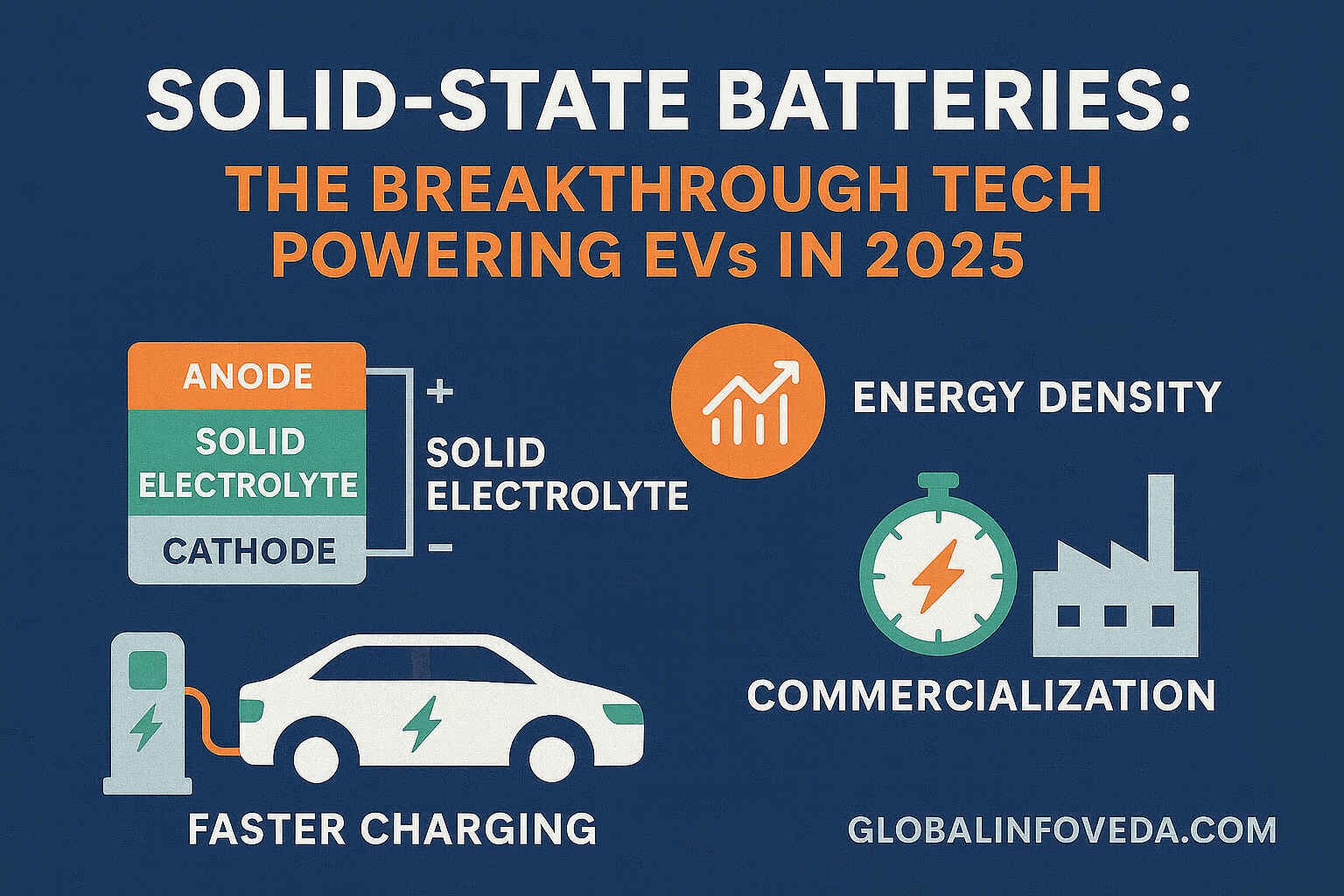

Solid State Batteries promise higher energy density, faster charge times, and safer operation than today’s lithium‑ion packs, and in 2025 the technology is coming off the lab hype cycle and onto early pilot lines and limited‑run EVs. In place of a flammable liquid electrolyte, they employed a solid electrolyte — ceramic, polymer, or its derivative — which enables them to go to even thinner lithium‑metal anodes, pack more tightly and be more thermally stable. The catch is a tall one: brittle materials, dendrite control and management, interface resistance, manufacturing yield, and cost. And for the Indian buyers and fleets and policymakers themselves, the real question isn’t whether solid‑state is exciting; it’s how they navigate the shift from today’s packs to tomorrow’s without losing sight of total cost of ownership, of charging infrastructure, of recycling. This field guide lays out the science, the economics, the India angle, buyer playbooks, and realistic timelines, so EV adoption speeds up without falling for vaporware.

Meta description: In 2025, solid‑state batteries move toward pilots. Understand benefits, risks, costs, India’s roadmap, buyer checklists, recycling, case studies, FAQs, and what changes next for EVs.

🧭 What counts as solid‑state in 2025

- 🧪 True solid electrolyte (ceramic sulfide/oxide or polymer composites) replacing liquid.

- 🪙 Lithium‑metal anode or ultra‑thin graphite‑silicon hybrids to raise energy density.

- 🧵 Stack pressure strategies to maintain interfacial contact and curb dendrites.

- 🧯 Thermal stability improvements lowering runaway risk and simplifying pack cooling.

- 🧰 Manufacturing that reuses parts of Li‑ion lines (dry rooms, calendering) with new steps for electrolyte lamination.

- 🧪 Hybrid cells (semi‑solid/gel) positioned as bridging designs for near‑term EV models.

🧠 Why the momentum is different now

Solid‑state had cycled through hype before, but 2024–5 brought intersecting signals: higher ionic conductivity in sulfide and oxide ceramics at room temperature; stronger interface coatings; better dendrite suppression from engineered stack pressure; and roll‑to‑roll pilot‑scale processes. On the demand side, charging corridors, two‑ and three‑wheeler electrification, and heavy fleet duty cycles mean that high‑density packs have value. Policy tailwinds — battery recycling mandates, local manufacturing incentives, and tighter thermal safety regs — push OEMs toward architectures that incur least cooling penalties. It’s still early in the story, but the trajectory of travel appears to be sturdy.

⚙️ Anatomy of a solid‑state cell

Cathode: usually NMC or high-voltage LNMO for energy, or LFP versions for cost/safety. Anode: lithium‑metal foil or lithium deposited on a host. Electrolyte : The electrolyte can be sulfide (high conductance, humidity sensitive), oxide (stable, but higher resistance), polymer (flexible, warmer operation), or composite stacks. The separator is integrated with the solid electrolyte layer. Current collectors and binders are like their Li‑ion cousins, but need to survive higher stack pressures. The pack can be simplified: fewer modules, more cell‑to‑pack designs, different thermal pathways, as runaway risk is less. But heat has to be dealt with even while fast charging and in high‑power operation.

🧮 Table — Technology paths at a glance

| Path | What it solves | What to watch |

|---|---|---|

| Sulfide ceramic | High room‑temp conductivity; thin electrolytes; fast charge potential | Moisture handling, H₂S risks in production, interface coatings |

| Oxide ceramic | Chemical stability; compatibility with high‑voltage cathodes | Higher interfacial resistance; pressure needs; brittle sheets |

| Polymer/composite | Flexibility, simpler lamination, lower cost tools | Warm‑temp dependence, lower conductivity, summer performance in India |

🌏 India‑specific realities

Fast‑growing buses and budget-sensitive cars account for the rest of India’s EV market. Solid‑state will probably be adopted first through high‑end imported vehicles or small fleet pilots, then trickle into the kinds of scooters and delivery vehicles where cycle life and safety with fast charging times are important to uptime. Monsoon conditions with humidity and ambient heat are tough on sulfide handling and polymer performance, factory dry‑rooms, sealed material flows and a well developed BMS are not for debate. On cost, cell‑to‑pack simplification and smaller cooling systems will go some way to offsetting that early premium but the sum total depends on localised supply chains, PLI incentives and recycling credits.

Energy Storage & Renewables: Stabilizing Tomorrow’s Power Grids

🚗 Where solid‑state helps the most

- ⚡ Fast charge with less heat for highway corridors and high‑utilisation fleets.

- 🧯 Safety headroom reducing thermal runaway risk and enabling denser packs.

- 📦 Packaging efficiency: higher energy density unlocks cabin or boot space.

- 🏁 Performance EVs: sustained high‑C discharge without aggressive cooling.

- 🚌 E‑buses: predictable depots + opportunity charging reward safer high‑cycle chemistries.

- 🛵 Last‑mile fleets: quicker turnarounds and lower incident risk in crowded cities.

🧪 Interfaces, dendrites, and pressure

The main technical drama occurs at the anode–electrolyte interface. Lithium metal expands/contracts as it plates/strips and is prone to creating voids and dendrites that short out cells. Several of these processes such as engineered pressure fields, elastic interlayers, sesquioxides, ceramic grain boundary tuning, and in situ formed SEI film are current remedies. The ability to control stack pressure through the wide range of temperatures in India’s hot summers without crushing brittle electrolytes is a necessity. Anticipate early EVs to marry solid‑state with conservative fast‑charge profiles and thermal pads that spread pressure and heat evenly.

💸 Economics — what makes the math work

- 🧱 Yield: scrap rates on brittle electrolyte sheets can dominate cost; gentle web handling and laser patterning are key.

- 🧰 Line reuse: repurposing Li‑ion coaters/calendering/dry rooms lowers capex.

- 🧪 Materials: lithium foil, high‑nickel cathodes, and sulfide powders drive BOM; composites reduce reliance.

- ❄️ Cooling simplification: safer cells mean lighter thermal systems, reclaiming cost and weight.

- 🔁 Cycle life: if a pack lasts longer before hitting 80% capacity, TCO improves even with higher upfront price.

🧮 Table — Today vs near‑term vs target

| Metric | 2025 pilots | Target (late decade) |

|---|---|---|

| Gravimetric energy | ~350–420 Wh/kg cell‑level | 450–500+ Wh/kg cell‑level |

| Fast charge | 20–30 min to 80% (controlled temps) | 10–15 min to 80% |

| Cycle life | 800–1,500 cycles to 80% | 1,500–3,000 cycles to 80% |

🧰 Buyer and fleet playbook

- 🧭 Specify use‑case: highway taxi vs city delivery vs private commuting.

- 📐 Right‑size packs: higher energy density lets you choose smaller packs if routes are predictable.

- 🧪 Ask for data: charge curves, temperature windows, cycle‑life at your ambient conditions.

- 🧯 Safety features: cell‑level fusing, pressure management, ventless pack designs, and BMS transparency.

- 🔁 Service/recycling: contracts that include end‑of‑life logistics and reuse pathways.

India’s Semiconductor Dream: “Made‑in‑India” Chips to Retail by 2025‑End

🔒 Safety, standards, and compliance

A solid‑state solves some of the hazards, but not all. Over‑charge, crush, or poor manufacturing could still lead to failure. Seek out compliance with the latest EV battery standards, strong pack validation (nail penetration, thermal soak, vibration), and obvious paths to recall. Depot staff should be trained in isolation, heat checking and safe quarantine principles of suspect packs. Fire brigades are still going to have protocols — safer here doesn’t mean easy.

♻️ Recycling and second life

- 🔄 Cathode recovery (nickel, cobalt, manganese) remains core; electrolyte forms shift but metals still matter.

- 🪵 Solid electrolytes complicate shredding; pre‑processing and selective dissolution will evolve.

- 🏠 Second‑life for stationary storage thrives if cycle life is strong and BMS data is portable.

- ♻️ Design for disassembly from day one cuts end‑of‑life costs and improves yields.

🧩 India’s manufacturing opportunity

- 🏭 PLI and state incentives can seed pilot lines near auto hubs; dry‑room capacity is the rate limiter.

- 🧪 Materials: domestic lithium is scarce; focus on electrolytes, current collectors, coatings, and pack innovations.

- 🧑🏭 Workforce: upskill Li‑ion workers for solid‑electrolyte handling; build safety culture around sulfide powders.

- 🔬 R&D consortia linking IITs, CSIR labs, and OEMs to iterate coatings and interface stacks.

- 🚚 Supply chain resilience: diversify away from single‑country dependencies with ASEAN/EU partnerships.

Samsung Starts Laptop Production in India—Localizing Tech for the Masses

🧪 Case study — Premium EV taxi fleet

A Bengaluru airport taxi operator trialled 50 solid‑state sedans on night‑heavy routes. Outcome: 18% higher uptime due to fast charge without mid‑shift cooling stalls; minor interface issues in peak May heat solved by adding pack‑level pressure shims. Accident rates unchanged; insurance premiums flat after underwriters reviewed thermal data. Drivers preferred the longer range buffer on airport detours.

🧪 Case study — Last‑mile e‑scooters

A Chennai delivery fleet swapped two‑thirds of its scooters to semi‑solid packs. Gains: 12 minutes faster turnarounds at micro‑hubs, lower incident risk in crowded lanes, and 9% drop in pack rejections after installers were retrained on torque and seals. Economics worked because cooling hardware and module complexity shrank.

🧪 Case study — E‑bus depot

A Pune operator ran 20 pilot buses with hybrid solid‑state modules on fixed routes. Depot opportunity charging plus lower thermal overheads kept schedules tight. Maintenance flagged dust intrusion as a real India problem; post‑monsoon inspections added gasket upgrades. Cycle‑life projections improved depot TCO enough to justify an order expansion contingent on recycling credits.

🧭 Myths vs realities

- ❌ “Solid‑state is 2× the range overnight.” Gains are real but tempered by pack‑level constraints and safety margins.

- ❌ “No cooling needed.” Heat still matters, especially at high C‑rates in Indian summers.

- ❌ “It’s here for everyone in 2025.” Expect premium niches first, then scooter/bus fleets, with mass adoption later.

- ❌ “No fires ever.” Risk drops; it doesn’t disappear.

🌞 Climate, monsoon, and heat

India’s climate is not an asterisk—it’s central. High humidity complicates sulfide handling; ambient 40 °C days stress polymer electrolytes; road dust punishes seals. Pack design must assume monsoon splash, pothole shocks, and depot dust. Insist on validation at Indian ambient extremes and insist on data access from the BMS. Charging bays need shade, airflow, and drainage as much as they need kilowatts.

🧭 Charging ecosystems that fit solid‑state

- ⚡ High‑power DC where grid allows; intelligent queuing to avoid heat bottlenecks.

- 🧊 Thermal aware chargers that taper smartly based on pack temp and pressure sensors.

- 🗺️ Route‑aware BMS that pre‑conditions packs on approach to chargers.

- 🔌 Urban hubs with short‑dwell top‑ups for scooters and autos.

Deep‑Tech Revolution at FITT Forward 2025

🧰 Design patterns that win in India

- 🧯 Cell‑to‑pack with fire‑breaks and pressure‑equalising layers.

- 🔧 Serviceable seals and dust‑resistant enclosures for depot realities.

- 🧪 Interface coatings tuned for humidity and vibration.

- 🧠 Data transparency so fleets can correlate heat, charge rate, and degradation.

🧮 Table — Buyer checklist by segment

| Segment | Key asks | Deal‑breakers |

|---|---|---|

| Scooter fleets | Rugged seals, quick top‑up, clear swap logistics | Hidden BMS data, heat‑fragile polymers |

| City cars | Home AC + occasional DC fast, efficient packs | Unproven recycling, vague warranty |

| Intercity taxis | Corridor DC, high buffer range, roadside support | No heat‑map data, slow charge in summer |

🧑⚖️ Policy levers that actually matter

- 🏭 Capex support for pilot lines and dry‑room expansions.

- ♻️ Recycling credits tied to real recovery yields, not declarations.

- 🧑🏫 Workforce skilling grants for electrolyte handling and pack assembly.

- 🧪 Testing labs for interface/pressure/thermal validation in Indian ambients.

- ⚡ Tariffs and supply diversification to derisk single‑country inputs.

🧠 How solid‑state interacts with other trends

- 🛰️ Autonomous features raise compute loads; energy density headroom helps.

- 🧠 AI‑driven BMS can predict hot spots, manage pressure, and adapt charge curves.

- 🏙️ Vehicle‑to‑grid and second life gain reliability if packs degrade slowly and safely.

- 🛠️ Local manufacturing dovetails with India’s electronics push, creating cross‑skill jobs.

AI Devices in 2025: Smart Glasses, Emotion‑Aware Assistants & Health Trackers

❓ FAQs

- Will solid‑state make EVs cheaper in 2025? Not immediately. Expect a premium that narrows as yields rise and pack simplification offsets costs.

- Is it safer? Generally yes due to solid electrolytes and reduced flammability, but design and BMS discipline still matter.

- How will charging change? Likely quicker top‑ups with smarter thermal limits; extreme heat will still cap rates.

- Can I retrofit an old EV? Rarely economical—new pack designs and BMS logics are tightly integrated.

- What about recycling? Metals recovery persists; electrolyte processing evolves. Choose brands with explicit take‑back plans.

🔬 Inside the factory — how lines actually evolve

Manufacturing solid‑state batteries at scale in India or anywhere isn’t a formulaic, liquid‑to‑solid‑electrolyte swap; it’s like a dance between the controlled dry room, handling of a web, lamination pressures and post‑process conditioning. A pragmatic line begins by repurposing valuable technologies from that of lithium‑ion—blending it, coating it, calendaring it—then adds new ones where the solid layer is to be cast, sintered (for ceramics), or laminated (for polymers/composites) devoid of micro‑cracks. The worst parts are the ones you can’t see: nanoscale voids on the anode–electrolyte interface, pinholes that beckon dendrites, edge chipping when we slit these rolls. Indian production plants also need to decelerate humidity loads during monsoon season, which makes enclosure design, sealed material transfer and desiccant staging as strategic as cathode chemistry. Initial yields will be lumpy; world‑class plants deal with this problem using tireless in‑line metrology—laser stylus thickness maps, infra‑red thermal scans following lamination and machine‑vision that spots grain boundary defects before they can be passed downstream. Training technicians to read these signals — and to shut down lines instead of ramping up damaged rolls to the end — will separate headline pilots from reliable supply.

🧪 Dendrite control in tropical heat — a practical playbook

- 🛡️ Interface engineering: apply ultra‑thin ceramic or polymer interlayers that deform elastically under stack pressure, keeping contact uniform as lithium plates and strips.

- 📏 Pressure homogeneity: use distributed springs or elastomer pads across modules so pressure does not pool at corners when ambient temps swing from 20 °C AC rooms to 40 °C yards.

- 🌡️ Thermal guardrails: cap charge above 80% SOC on the hottest afternoons, and allow brief pre‑cooling before high‑power DC sessions; integrate pack‑level heat‑soak sensors.

- 🧬 Electrolyte tuning: favor grain sizes and dopants that resist crack propagation; in polymers, hybridise with ceramic fillers to raise ionic conductivity without losing flexibility.

- ⚡ Charge‑curve shaping: ramp current smoothly at the start, flatten mid‑range, and taper early; this reduces interfacial stress spikes where dendrites nucleate.

- 🧪 Formation cycles: adopt slower, temperature‑controlled formation for the first dozen cycles to build a robust, uniform SEI that survives India’s stop‑go traffic.

- 🧰 Edge protection: coat and seal cell edges to avoid moisture ingress and edge‑initiated dendrites from microscopic mechanical damage.

- 🧠 BMS intelligence: use impedance tracking and pressure sensor fusion to detect early anomalies; schedule conditioning charges during cooler night windows.

- 🧯 Abuse testing: simulate curb hits and pothole shocks while hot; verify that pressure frames recover elastically and do not over‑stress brittle electrolytes.

- 🔄 Field feedback loops: push anonymised pack data back to materials teams monthly so electrolyte recipes evolve with real Indian heat maps.

📊 TCO in real rupees — why the premium can still pay

Think of a city taxi driving 220km/day, five days a half week, 63000km/year. So if I get just 12% energy efficiency benefit from mass reduction and cooling simplification by a solid-state pack, that’s 1,260kWh saved per year at 0.18kWh/km—₹12,600–₹18,900 per year difference in city tariffs. Add 2 (fewer) midday cooling slow‑downs per week (15 min) and you get about 26 productive hours a year i.e. 10s of 1000s of ₹ of time. Introducing direct from India with a ₹1.2–₹1.8lakh upfront premium and 3y guarantee cycle life and buy‑back when tip total cost of ownership positive, and the operator sells into airport night corridors and fast charge headroom that protects schedules. For last‑mile scooters, the math is different but still compelling: 8–10 minutes saved from a full‑up (times about thirty swaps per week) adds up to an extra few hundred deliveries in a year. Transit fleets don’t really care about headline range, but about predictability; safer cells and simpler cooling mean less unexpected depot outages and mechanics’ time, and that’s where the real money lies.

🏙️ City pilots that make sense for India — blueprint

- 🧭 Delhi‑NCR: pair corridor DC fast on the Eastern & Western Peripheral Expressways with depot shade structures and misting fans; monitor pack temps during May–June heat.

- 🌧️ Mumbai: design for monsoon splash—raised conduits, drain grates, and IP‑rated enclosures; schedule high‑power sessions in drier windows.

- 🌡️ Bengaluru: traffic crawl demands thermal‑aware chargers at malls and tech parks; encourage top‑ups at 40–60% SOC to flatten heat spikes.

- 🌊 Chennai: salt air near the coast requires corrosion‑aware pack housings; micro‑hubs for scooters with canopy shade and airflow trump raw charger count.

- 🚌 Pune/Hyderabad: depot‑centric e‑buses benefit from night formation cycles inside temperature‑controlled sheds; integrate BMS data into route planning.

- 🚨 Emergency protocols: dedicate a quarantine bay at depots for suspect modules; train staff in isolation procedures and remote BMS lockouts.

- 🧰 Maintenance cadence: post‑monsoon gasket audits and connector torque checks; replace dust filters proactively rather than reactively.

- 🔁 Data contracts: ensure anonymised cell‑level data returns to OEMs monthly so materials and charge curves evolve within a single season, not a fiscal year later.

🛡️ Warranty, data rights, and procurement clauses that protect you

With solid‑state pilots, contracts should connect warranty to ambient‑corrected cycle life, not generic numbers written for cooler climates. Demand access to BMS data as a right, with export formats and retention periods clearly defined; without that metadata, operators cannot separate abuse from materials drift. Institute regular safety drills for depots, and include a design for disassembly clause so that end‑of‑life costs won’t be a shock to the system. A fair buy‑back or second‑life path should be in writing, tied to remaining capacity as confirmed by third‑party tests. And last but not least, ban unilateral OTA throttling of charge rates without thermal proof on the record; else a midsummer software update can quietly remove the reason you paid for fast charging.

🌐 Players and partnerships in 2025 — what matters more than logos

Everyone is obsessed with brand names, but it is the quality of integration that determines what IT buys. The winning combinations are a cell maker with a track record of shipping interface coatings, a pack integrator with a rate of production of cell-to-pack fire-breaks, and a vehicle OEM willing to fruit telemetry to a fleet partner. In India, collaborations with component suppliers who can machine or source dust‑tight enclosures, make reliable harnesses and provide service training at scale are proving more fruitful than sexier claims about Wh/kg. As much as chemistry, freight and customs predictability can be a difference maker, he said; a slightly heavier but locally serviceable system can outpace a cutting‑edge import that idles in transit. And the utilitarian question for the purchaser is not “Who is the hottest lab?” but “Whose packs kept running through April heat and July rain, and who answered the phone at 2am?”

♻️ End‑of‑life logistics that actually work in India

The real recycling is more than a press release. Operators must pre‑register with collection partners capable of receiving mixed streams when solid electrolytes prevent shredding and leaching. Traceability counts: tag modules at birth so second‑life allocation into commercial buildings or micro‑grids can be audited. Labour safety is not up for discussion – sulfide dust and H₂S applications need ventilations and the sensors, whereas the shards of oxide is in need of eye/hand protection and cautious bagging. A decent program tells you the recovered yields on nickel, cobalt, manganese and copper, not just the input tonnage. Design teams can address these issues with fasteners instead of glue, clear pull‑tabs, and connectors that hold up to two removals without deformation. All the shortcuts that you take during assembly are bills that you receive when end‑of‑life comes; the cheapest pack to manufacture is usually the most expensive to recycle.

🧑🔬 Electrolyte families — choosing for climate and duty

In a racing analogy, sulfides are the sprinters: excellent at room‑temperature ionic conductivity and for the promise of thin membranes for fast charging. But they despise wet and their way of manufacturing produces H₂S, so Indian factories have to operate strict dry‑rooms, inert gas purges, and sealed transfer enclosed corridors. Oxides (e.g., garnet‑type) are relatively stoic and chemically stable and fine with high‑voltage cathodes, but stiff and resistant to intimate contact, unless there is greater pressure and a smooth surface finish. Polymers are manufacturing-friendly — lay down, press, go — but require warmer conditions and fancy fillers to help maintain the conductivity, something that’s challenging on those toasty summer peak demand days. The pragmatic bridge from here to 2025–2027 is composite stacks that offer the best of both polymer flexibility and ceramic islands, particularly in market segments where safety and ease of lamination matter more than chasing every last Wh/kg.

📈 Investor view — what to underwrite and what to avoid

- 💵 Back yields, not press releases; require month‑by‑month scrap curves from pilot lines.

- 🧪 Fund interface science (coatings, interlayers) where small breakthroughs cascade across models.

- 🧰 Prefer platforms that reuse Li‑ion tooling; capex light beats moon‑shot plants that start from zero.

- 🧯 Insist on safety telemetry access; it lowers insured risk and improves underwriting.

- 🌏 Diversify inputs beyond single‑country reliance for electrolyte powders and foils.

- 🔁 Tie capital to clear recycling yields and second‑life revenue sharing.

- 📦 Bet on pack integrators with service networks in Indian metros and tier‑2 cities.

- 🧑🏫 Support workforce training; technician quality is a competitive moat in hot, dusty markets.

- 🕒 Timeline realism: expect staged revenues—premium imports → fleets → mass scooters/buses.

- 📉 Avoid hype flags: no transparent BMS data, vague pressure specs, or claims that ignore ambient heat.

🧭 Roadmap 2025–2030 — what changes when

Only on premium EVs and some fleets from 2025 to 2026 will continue to fly the banner, mostly with composite or hybrid structures. With yields on the rise and cell‑to‑pack architecture making cooling easier to design in, 2027 (or so) brings scooters and compact city cars where every kilogram of saved weight translates into extra deliveries or cabin space. Oxide‑heavy stacks might make higher cycle life targets for intercity taxis and e-buses by 2028–2029 New assembly for more of it in India to win on logistics and service speed. The number to watch is not the headline range; it is when warranty terms pivot away from time‑bound to energy‑throughput bound, indicating confidence in degradation curves. By 2030, with a supply of well trained technicians, predictable yields in recycling, and multi‑city charging standards, solid‑state will be a regular consideration, not a novelty.

🏁 What buyers should do this quarter — a short, sharp to‑do

- 📋 Map routes and dwell points; simulate charge windows at summer temps.

- 🔎 Audit depots for shade, airflow, drainage, and quarantine capacity.

- 🧪 Request packs for on‑road trials that include one pre‑monsoon and one post‑monsoon week.

- 📈 Log data: SOC, temperature, charge time, and pack pressure if exposed by the BMS.

- 🧑🏫 Train crews on seal checks, torque specs, and safe isolation procedures.

- 🔐 Negotiate data access and buy‑back clauses before placing orders.

- ♻️ Pre‑contract with recyclers; verify recovery yields and handling of solid electrolytes.

- 🔧 Stock spares: gaskets, filters, connectors proven to survive two removals.

- 🧠 Educate drivers on pre‑conditioning and smarter top‑ups; behaviour matters as much as chemistry.

- 🧭 Stage rollouts by city and duty cycle; avoid one‑shot national deployments.

🧪 Field notes — what early pilots usually miss

Early programs too frequently neglect the tedious but telling specifics: connector torque walk-up after a thousand potholes; condensation inside enclosures post AC‑to‑outdoor transition; depot fans that shoot dust straight into bays. The cure is boring engineering discipline — baffles and filters at air intakes, drain holes with mesh that blocks mice and checklists on which gaskets are a consumable. Behaviour tweaks can also help: promote top-ups while packs are resting in between, say, 35% and 65% SOC in the middle of hot days, and save 80–100% pushes for cooler nights. A culture of documenting near‑misses — smells, hot spots, error codes — recategorizes minor events as design data, not social‑media drama.

📚 Sources

- International Energy Agency (IEA) — Global EV Outlook: adoption, battery trends, and charging scenarios. https://www.iea.org/reports/global-ev-outlook

- U.S. Department of Energy (DOE), Vehicle Technologies Office — solid‑state R&D highlights and Battery500 Consortium updates. https://www.energy.gov/eere/vehicles/vehicle-technologies-office

- European Battery Alliance / EU Commission — industrial roadmap for advanced batteries and safety frameworks. https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/european-battery-alliance_en

- Ministry of Heavy Industries (Govt. of India) — FAME India Scheme and advanced chemistry cell programme. https://heavyindustries.gov.in

🧠 Final insights

Solid‑state batteries aren’t magic — though they are significant. Watch for early wins in premium imports and structured fleets, then in scooters and buses as yields rise and pack designs mature. The benefits — in energy density, quicker charging, thermal safety — are weighed against manufacturing realities, humidity, dust and cost curves that only bend as demanding pilots and candid data beseech them.Win-win in the desert: Prototype desalination system aims for extra water and powerGovernments have long promised they would be the ones to help the world get to such a future. For India, success takes the form of local materials know‑how, a strong BMS, weather‑proofed depots and a recycling process that captures value. If customers right‑size packs, If fleets demand data, If policymakers fund R&D and workforce skills, EVs can be adopted more rapidly, without any safety trade‑offs. That’s how this tech makes the leap from promising slides to common roads.

👉 Explore more insights at GlobalInfoVeda.com